Is something amiss in your electric bike? Electric bikes just go to show how far technology has gone. It’s now been four years since I had my first e-bike. The experience has been a thrilling one.

But, if there is one thing with e-bikes that you must know, then it’s maintenance and troubleshooting and electric bike hub motor problems are a must. I’ve experienced it a couple of times by myself!

So, what are electric bike hub motor problems? Electric bike hub motors can suffer from loose wiring, worn-out gears, breaks, and bearings. The problems usually lead to hub motor noise.

Key Takeaways:

- Avoid opening your electric bike hub motor. Doing so can void the warranty. You also need to take extreme care when handling electrical components and loose wires.

- Hub motors feature a simple structure and are reliable with a small torque vibration and low noise.

- Worn-out gears, brakes, bearings, and loose wiring can greatly impact the performance of an electric bike.

- Always make sure the hall sensor syncs with your motor. You can always test this by running a voltage test.

A problem with the controller can also affect the spinning. Looking to learn more about your electric bike hub motor issues. Keep reading below.

What Are The Leading Bike Hub Motor Problems?

There are various bike hub motor problems, but the major two problems are with phase wires and hall sensors.

A phase wire problem occurs when there is an internal wire cut or a cut on the jack.

The second major issue is a hall sensor problem where there is a problem with the wire connected to the sensor.

But what leads to these two major problems? Hall sensors can fail due to overheating by the motor. Sensors are designed to withstand certain temperatures. When you overload and have the motor heating, sensors can fail.

Wiring issues are also common in e-bikes leading to hub motor problems. Weak and loose wires can cause faulty connections.

Connectors that are not properly plugged in can also cause bike motor problems.

Another third problem that bike hub motors experience is motor noise. Motor noise is a common issue caused by worn-out bearings, disk brakes, or worn-out gears. Hub motor noises can also happen due to loose bolts.

Electric Bike Hub Motor Troubleshooting and Diagnosis

Now that you know the main electric bike motor issues, how do you fix them?

The first step is diagnosing the problem. However, this can be tricky if the motor is still under warranty. Opening the motor can void the warranty.

Secondly, dealing with connections and electric wires can be dangerous. If you have a little experience with electrical components, avoid testing the motor.

Fix only what you can and leave the rest to professional electricians. With all these in mind, let’s see the steps you can take to fix electric bike hub motor problems.

Check The Switches

Your bike hub motor not starting can be a simple switch issue. Is the ON/OFF functionality working?

Check the motor controller and ensure the switch is working. Does the controller stutter? Is it activating?

Make sure connections are not weak or damaged. Ensuring the on and off switch is working can avoid most hub motor problems.

Inspect Motor Wiring

Next, you want to make sure all motor wiring is working efficiently. Loose and weak wiring to the battery, motor, and controller can lead to a faulty hub motor.

Disconnect the hub motor and check the connectors. Sniff the wires to check for a burning smell.

Motor overheating can lead to the melting of plastic parts. A powerful plastic or rubber odor indicates overheating of the motor.

Hall Sensor Testing

You also need to test the hall sensor wiring and connections. There are three hall sensor wires with voltage input that you must check.

A multimeter device is required to test the hall sensor connectivity. The multimeter needs to generate a readout when you connect two ends of the hall sensor.

If any of the three wires connecting the sensor fails, motor controller operations are affected.

Inspect Rear-hub Motor

You can also check the connecting wires to a rear-hub motor. Wires can get loose after riding on rugged terrains or carrying heavy weight.

Most rear-hub motors suffer fraying, which can affect motor functionality. Fraying is a common issue that affects all types of motors.

Why Do Hall Sensors Fail?

The main reason for hall sensors failing is overheating. The high heat from the motor beyond normal can damage the hall sensor. When buying a new hall sensor, consider models that can withstand high temperatures.

But why do hub motors overheat? Now that you know excess heat from motors is a big problem, it makes sense to know the cause.

Reasons why hub motors overheat

Overload is the main cause of motor overheating. Motors produce constant power. However, they can be forced to work more when motor bearings are broken.

- Higher voltages that are 10% more than rated voltages can lead to motor overheating.

- Wiring problems can also cause motor overheating. When wiring systems are poorly connected, they can heat and transfer the heat to the motor.

- Motor with long rotors and high power suffer a rotor effect which causes overheating.

- Poor motor bearing systems and ineffective greasing can cause the wheel hub motor to overheat.

If you can reduce overheating of the hub motor, then you can greatly reduce most hub motor problems.

How To Replace A Hall Sensor

If you detect the hall sensor is the problem, then determine whether to fix or replace it. Small wiring issues can easily be fixed by tightening loose connections.

However, if the hall sensor is damaged by either overheating or something else, then replacing it makes sense.

The process of replacing is simple when you have the right tools. Below are three basic tools you need.

- New hall sensor

- Soldering iron

- Screwdriver

You can then follow the steps below to replace a damaged hall sensor.

Step-1: Disconnect the hub motor sensor.

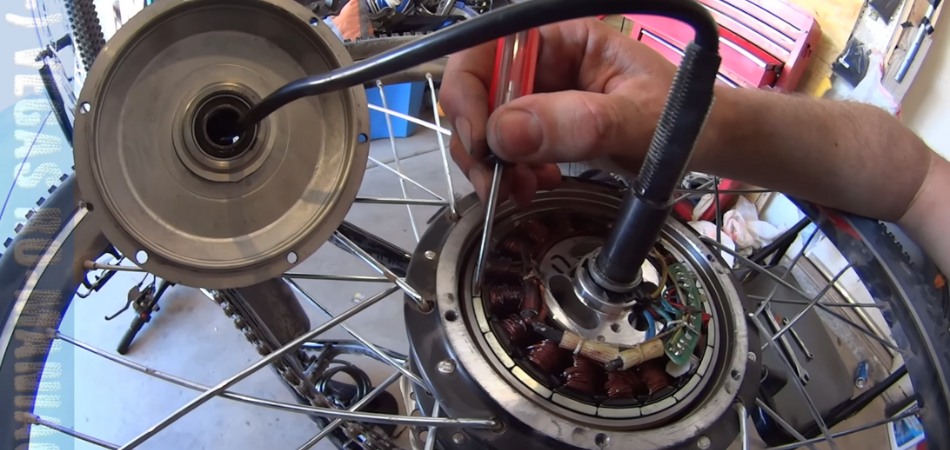

Step-2: Open and remove the outer motor cover using an appropriate screwdriver.

Step-3: Locate the damage sensor and take a screenshot of how it’s fixed. This will help you when fixing a new sensor.

Step-4: Using a soldering iron, carefully remove the sensor without damaging other connections

Step-5: Install the new sensor facing the same direction as the old sensor. Use images of the screenshot to help with the installation.

Step-6: Solder loose parts with a soldering iron.

Step-7: Test the motor to ensure the sensor is working.

Step-8: Finish by covering the motor and screwing everything back in place.

FAQ’s

Have a few more questions remaining in your mind if so then check out the below FAQ section, you’ll get the answers to most of your queries.

Why is my eBike motor not working?

Your eBike motor is not working because of problems with the motor or a dead battery. Check if the battery is charged and working. Next, make sure the motor switches, connections, and hall sensors are working.

Can you test an e-bike hub motor without a controller?

You can test an electric bike hub motor without a controller by simply inspecting the components. Check and see if there are loose wire connections.

However, to perform a full diagnostic test, you need a controller.

How do you troubleshoot a hub motor?

You can troubleshoot a hub motor by first finding the cause of the problem. Diagnose the hub motor by checking the switches, wiring, and hall sensor using a multimeter.

Once you detect the cause of the problem, go ahead and fix it or replace the damaged part.

How do you test a hub motor with a multimeter?

You can test a hub motor with a multimeter by connecting the two prongs of the multimeter to the hub motor sensor. This should be able to generate a readout.

Compare the readout with the rated voltage in the manual to detect any abnormality.

You May Also Read: Why Electric Bike Display Not Working?

Final Verdict

Electric bike hub motor problems are common but easy to diagnose and fix. As a general rule, use a multimeter or electric bike tester to check poor motor connections. The wire phase and hall sensor need to show a reading if they are working. Otherwise, check for any loose connections and fix them.

Avoid opening a motor under warranty as it can void the warranty. If you have little experience with electrical wiring, consider hiring a professional to check out the motor for you. Operating electrical components can be dangerous. Having said that, diagnosing and solving electric bike hub motor problems is easy.

Follow our guidelines above, and you’ll solve any issues with your hub motors.